Material :

Stainless SteelColor :

MetallochromeShape :

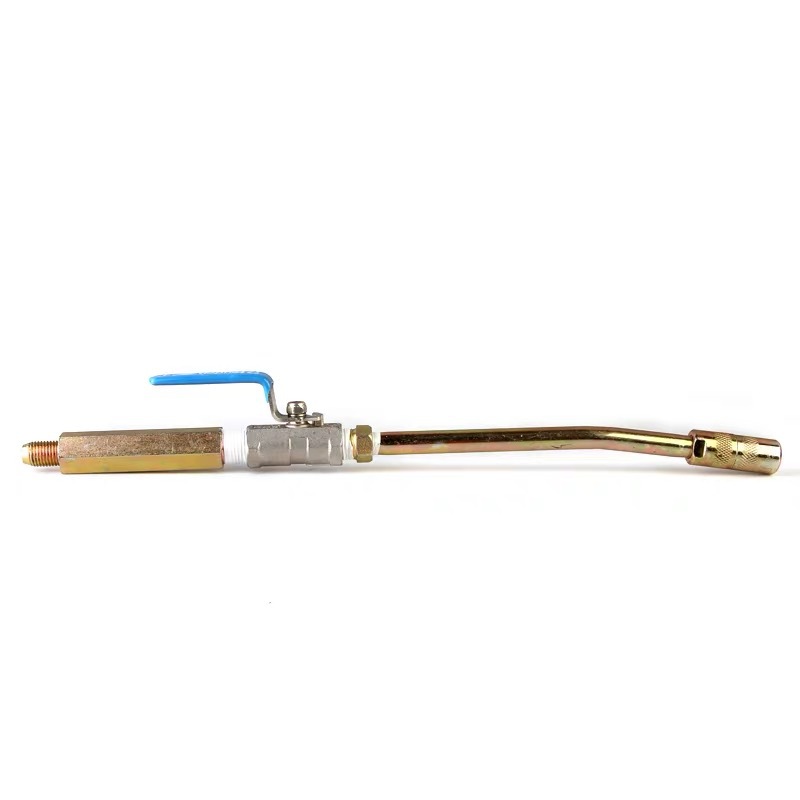

SquareUsage :

Engineering Construction WaterproofingType :

Parts Of The Injection MachineFormat :

LayeredFunction :

Connect Grouting Machine With Injection PackerApplication :

Construction JointItem No :

Grease CouplerProduct Origin :

ChinaOrder(MOQ) :

100 PiecesPayment :

T/T,L/CShipping Port :

Shanghai, Shenzhen, Ningbo...Video Description

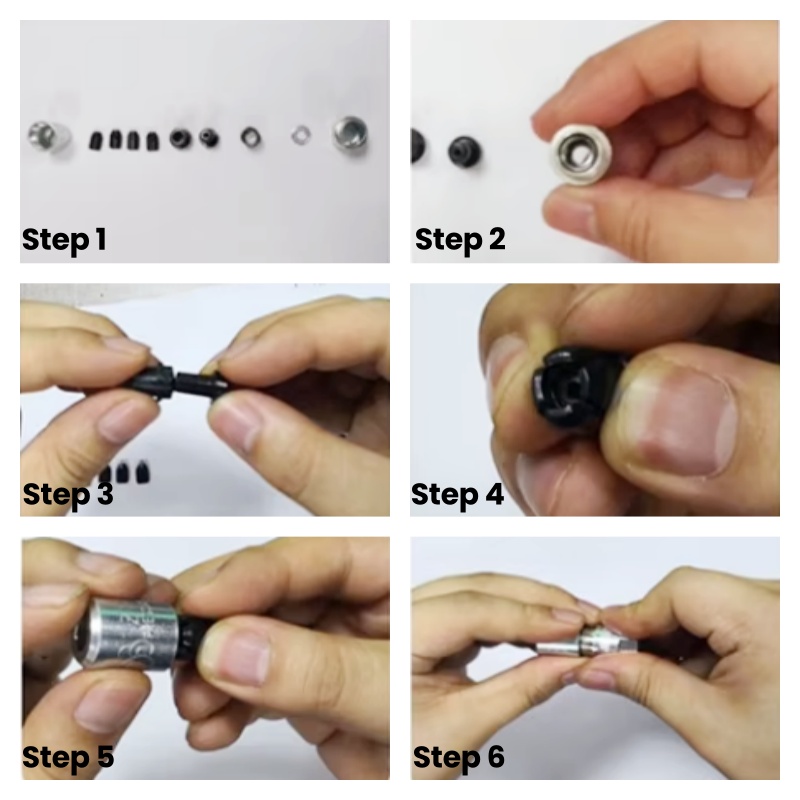

Installation Tutorial

Step 1: Remove the shell and place the gasket, steel ball, and spring in sequence

Step 2: Place the installed casing aside

Step 3: Install the rubber pad and the rubber pad fixing seat

Step 4: Install the gasket

Step 5: Install the upper shell

Step 6: Close and tighten the two shells

Precautions For Use:

1.Leakage of slurry from the butter nozzle during infusion

Reason and method:

The rubber pad inside the butter head is worn, the butter head is disassembled, the rubber pad is replaced, and the assembly is completed and reinstalled.

2.During infusion, the butter head and the water stop needle are loose and cannot be connected

Reason and method:

The butter head or four claws are worn out, and the butter head should be replaced with a new one. The black sealing gasket is used on the surface of the butter head. When subjected to high pressure, the black rubber gasket inside will rapidly expand, and the four pressure plates will tightly wrap the grease nozzle on the needle. This way, even under high pressure impact, the rubber gasket will not deform or be damaged, so the material that needs to be injected will not cause leakage. It should be noted that the rubber gasket inside the butter head will be damaged under high pressure impact for a long time. The solvent and solvent cleaning of the chemical grouting material can also cause damage to the sealing gasket and leakage. In this case, if any leakage is found, it should be replaced in a timely manner.

Our Services

√ Customizable Logo

√ Customizable Packaging

√ Online Technical Support Available

√ Can Undertake Construction Projects